The economical solution in construction industry for the separation and filtration of drilling and sawing slurry

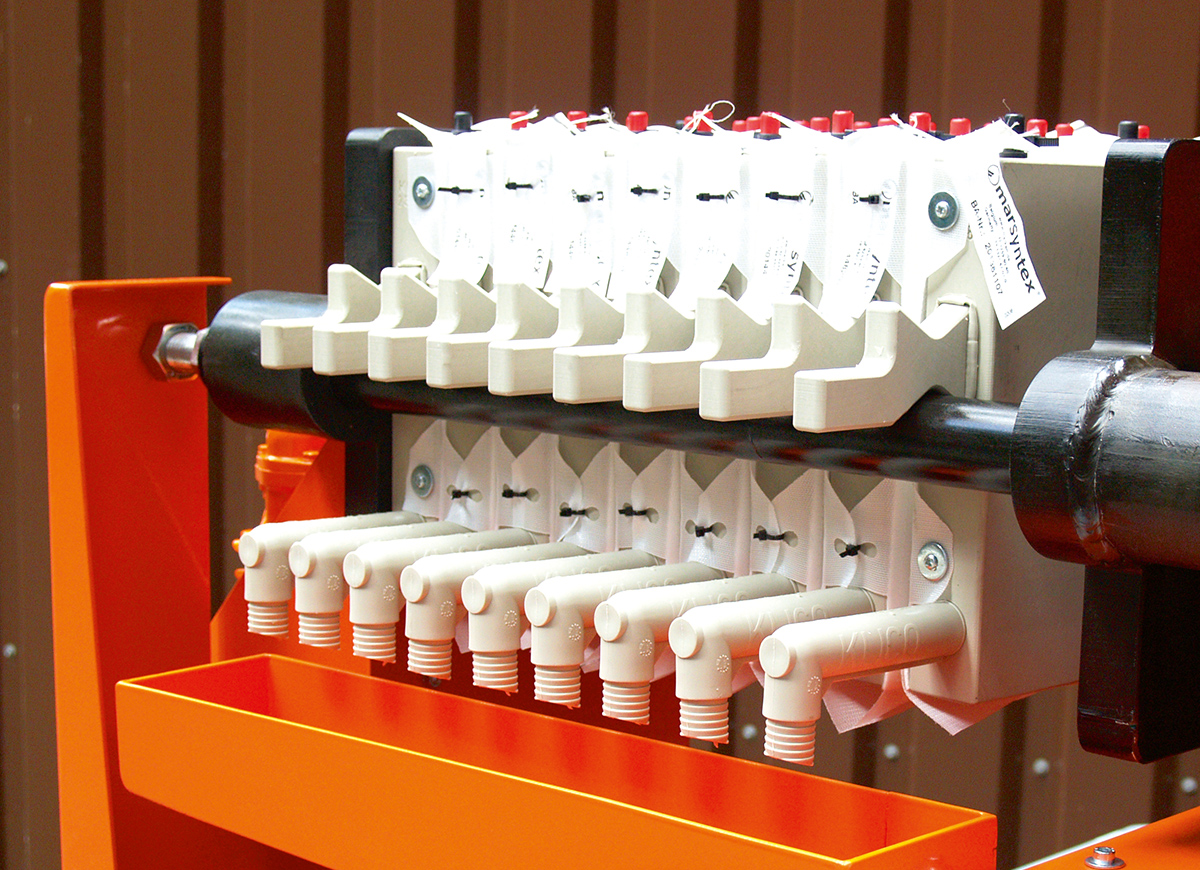

Powered 100% by air, the new SFP 8L is the portable solution for concrete slurry processing. Separation of solids and water allows for compliant disposal.

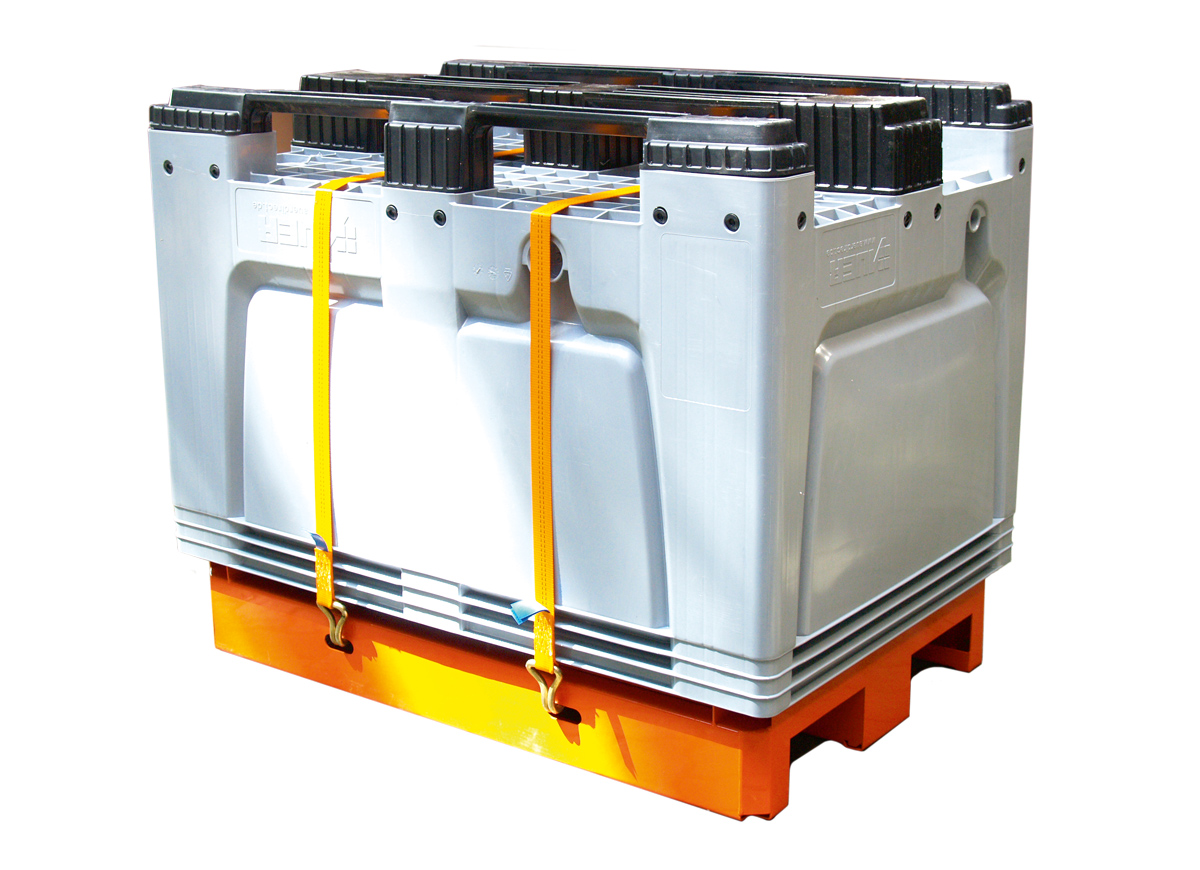

Consisting of four elements: container, chamber filter press, control unit and air compressor. Compact, simple to operate and efficient.

The included slurry box has a capacity of 140 gal (400 l) and can be used as cover during transport.

Because of its compact dimensions the SFP 8L can be used at each workplace.

Its innovative system and compact dimensions make thein.Slurryfoxin. an economical and ecological benefit.

GÖLZin.Slurryfoxin. is the new solution to compliant slurry disposal.

Innovative and environmentally friendlySpecifications

|

US Standard |

Metric |

| Operating |

100% pneumatic |

| Air required |

80 gal / 90 psi |

250 l / 6 bar |

| Recycling Capacity |

120-160 gal/hour |

450 – 600 l/Std |

| Filtervolume (solids) |

1,7 gal |

6,4 liter |

| Dimensions (LxWxH) |

48×32×64 in. |

1200×800×1.620 mm |

| Weight |

700 lbs |

320 kg |

| Order number |

0284 000 1000 |

| Additional-Slurry box |

| Dimensions (LxWxH) |

48×32×31 in. |

1200×800×790 mm |

|

|

Recommended Air Compressor

| Air compressor |

UNM 410 or (Ingersoll Rand P1.5IU-A9) |

| Motor |

Single Phase 230 V, 2,2 kW (115 V- 1,5 kW) |

| Capacity |

89 gal/min |

340 l/min |

| Airpressure |

116 psi |

8 bar |

| Compressor Unit |

2 cylinder – 1.450 rpm |

2020 Brew by Coffee Creative Studio

2020 Brew by Coffee Creative Studio